There are several temperature element instrument types widely applied to measure the temperature of a process substance. These instruments are divided into two main categories: mechanical temperature elements and electronic temperature elements. Mechanical temperature elements operate on the principle of thermal expansion, meaning the element expands when the temperature increases and contracts when it decreases. Electronic temperature elements use the principle of electrical properties changing in response to temperature variation.

Mechanical temperature elements rely on the physical expansion of a material when heated. These devices are valued for their simplicity, durability, and ability to function without an external power source.

A bimetallic temperature element instrument consists of two metals with distinct thermal expansion characteristics. These metals are bonded together to form a single strip. When the temperature changes, the metal strip bends. A pointer attached to the free end of the bimetal strip indicates the temperature measurement result.

A gas-filled temperature element instrument operates based on the ideal gas law. It comprises a bulb/stem, a capillary tube, and a Bourdon tube. The sensing component is a rigid bulb or stem filled with gas. When the temperature increases, the volume remains constant due to the rigidity of the bulb, causing the gas pressure to rise proportionally. This change in gas pressure is detected by a pressure element such as a Bourdon tube.

The bulb and Bourdon tube are connected via a capillary tube, allowing the temperature indicator to be positioned away from the piping or vessel being measured. This setup offers the advantage of placing the temperature gauge in a convenient location, even if the process fluid’s tapping point is not easily accessible.

However, the capillary tube may lose heat, necessitating the addition of compensation mechanisms to eliminate potential errors.

A liquid temperature element employs mercury confined within a bulb and stem. Although mercury offers quick response and high accuracy, it is no longer favored in most process applications. Instead, mercury is primarily used in glass stem thermometers for non-process industries, such as measuring body temperature.

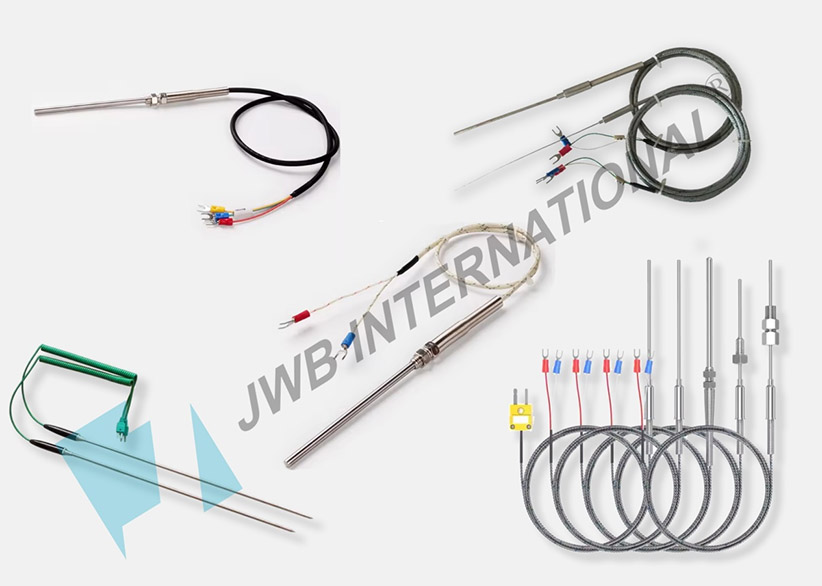

Electronic temperature elements measure temperature by detecting changes in electrical properties caused by temperature variation. The two most commonly utilized types are the Resistance Temperature Detector (RTD) and the Thermocouple. This category also includes structural variations like the flexible thermocouple probe, which offers enhanced installation flexibility while maintaining the same measurement principles. For these elements to indicate temperature measurements, they must be connected to a control system either directly via wiring or through the use of a temperature transmitter. Electronic temperature elements are widely used in modern process industries for their accuracy, versatility, and compatibility with control systems.

A Resistance Temperature Detector (RTD) operates on the principle that a metal’s resistance changes with temperature. RTDs are widely used in process measurement because they offer excellent stability, accuracy, and repeatability.

A thermocouple is made up of two different metals that produce a voltage corresponding to the temperature at their junction. Thermocouples are chosen for applications that demand a broad temperature range, from very high to very low temperatures. Additionally, thermocouples have advantages over RTDs, including a more robust design and quicker response times.

Temperature measurement instruments are essential for process control, safety, and efficiency. Mechanical-based temperature elements offer durability and independence from power sources, making them ideal for certain field applications. Electronic-based elements provide higher precision, faster response, and easier integration with modern control systems. Selecting the right thermo element depends on factors such as temperature range, accuracy requirements, environmental conditions, and installation constraints.