A heating element is a component or material that transforms electrical energy into thermal energy through a mechanism known as Joule heating. This phenomenon takes place when an electric current passes through a conductor, leading to collisions between electrons or charge carriers and the atoms or ions of the conductor. These interactions create friction at the atomic scale, which manifests as heat. The heat generated by this process is quantified by Joule’s first law (also known as the Joule-Lenz law), which can be formulated as:

P = IV or P =I²R

Based on these equations, the amount of heat produced is influenced by the current, voltage, and the resistance of the conductor. In the design of heating elements, the resistance of the conductor plays a vital role.

Joule heating occurs in all conductive materials to varying degrees, except in superconductors. In general, materials with low electrical resistance produce less heat because charge carriers flow more easily through them, whereas materials with high resistance generate more heat. Superconductors allow electrical current to flow without producing any heat. Typically, heat generated by conductors is considered an energy loss. Electrical energy used to power equipment often results in unwanted heating, known as copper loss, which does not contribute to useful work.

Electrical heating elements are almost 100% efficient in converting electrical energy into heat, as nearly all the supplied energy is turned into thermal energy. These elements can also emit energy as light and radiation. However, this high efficiency is typically true only for resistors. Minor losses can occur due to the material’s inherent capacitance and inductance, which convert electrical energy into electric and magnetic fields, respectively. Additionally, the overall system efficiency can be impacted by heat loss to the surrounding environment from the process fluid or the heater itself. To maximize the effective use of the generated heat, the heating system should be well-insulated.

Almost all conductors produce heat when an electric current flows through them, but not all are suitable for heating elements. The ideal material for a heating element must have a specific set of electrical, mechanical, and chemical properties. Key properties for effective heating element design include:

Resistivity: The heating element needs sufficient electrical resistance to generate heat, but not so much that it acts as an insulator. Electrical resistance is calculated as resistivity times the length of the conductor divided by its cross-sectional area. For a given cross-section, a material with high resistivity is used to keep the conductor short.

Oxidation Resistance: Heat accelerates oxidation in metals and ceramics, which can degrade the heating element’s capacity or structure, shortening its lifespan. Metallic heating elements often use alloys that form a protective oxide layer to resist oxidation. Ceramic elements commonly use SiO2 or Al2O3 scales for protection. Materials like graphite, which are unsuitable for oxidizing environments, are used in vacuum furnaces or furnaces with non-oxidizing gases like H2, N2, Ar, or He.

Temperature Coefficient of Resistance: The resistivity of materials changes with temperature. In most conductors, resistance increases as temperature rises. This effect is more pronounced in some materials. A high temperature coefficient of resistance is useful for heat-sensing applications, while a lower value is generally better for heat generation. In some cases, a sharp increase in resistance is desirable for delivering more power, and control or feedback systems are used to adjust for changing resistivity.

Mechanical Properties: Heating elements can deform at high temperatures. As materials approach their melting or recrystallization phases, they weaken and deform more easily. A good heating element maintains its form at high temperatures. Ductility is also important, especially for metallic elements, allowing them to be shaped without losing tensile strength.

Melting Point: The operating temperature of a material is limited by its melting point and the temperature at which oxidation significantly increases. Ceramics generally have higher melting points than metals.

· The material properties previously mentioned help narrow down the selection to a few key materials. Commonly used materials include nickel-chromium alloy, iron-chromium-aluminum alloy, molybdenum silicide, and silicon carbide, all of which are ideal for high-temperature applications due to their oxidation resistance. Another category comprises graphite, molybdenum, tungsten, and tantalum. These materials are susceptible to oxidation at high temperatures and are thus generally used only in vacuum environments or furnaces with oxygen-free atmospheres.

Nickel-chromium alloys are widely used for heating elements due to their excellent ductility, high resistivity, and strong resistance to oxidation at high temperatures. These alloys typically consist of 80% nickel and 20% chromium, although variations in composition can be found from different manufacturers. Their high ductility allows them to be easily formed into wires, which are commonly used in applications like hot-wire foam cutters. These wires can achieve maximum heating temperatures ranging from approximately 1,100 to 1,200°C.

Iron-chromium-aluminum alloys usually comprise 20 to 24% chromium, 4 to 6% aluminum, with the rest being iron. These alloys are appreciated for their flexibility and lower density relative to nickel-chromium alloys. They are capable of reaching higher temperatures, approximately 1,300 to 1,400°C. These alloys are generally more affordable due to the lower price fluctuations of iron compared to nickel. However, they exhibit diminished strength at high temperatures when compared to nickel-chromium alloys.

Iron-chromium-aluminum alloys can be improved using powder metallurgy techniques. In this method, the alloy ingot is pulverized into a fine powder, which is then compacted into a die and either sintered or hot-pressed under a controlled atmosphere. This process forms a metallurgical bond without completely melting the powder. To enhance the mechanical properties of the material, dispersoids are incorporated, which boosts its strength and toughness at elevated temperatures.

Molybdenum disilicide (MoSi₂) is a refractory cermet, a composite material combining ceramic and metallic properties, primarily used as a heating element. It is ideal for high-temperature furnaces due to its high melting point and excellent resistance to corrosion. MoSi₂ heating elements are produced through various energy-intensive processes, such as mechanical alloying, combustion synthesis, shock synthesis, and hot isostatic pressing.

MoSi₂ heaters can achieve temperatures up to 1,900°C. However, they have certain limitations, including low toughness at room temperature and vulnerability to high-temperature creep. At ambient temperatures, MoSi₂ is brittle and must be handled with care. Its toughness improves significantly at its brittle-ductile transition temperature of around 1,000°C. Despite this, a higher creep rate can lead to deformation at elevated temperatures. The most common design for MoSi₂ elements is the 2-shank hairpin type, typically suspended from the furnace roof and arranged around the furnace walls. Other configurations are available and are often combined with ceramic insulation formers to provide both mechanical support and thermal insulation in a single unit.

Silicon carbide heating elements are crafted from a ceramic material formed by recrystallizing or reaction bonding SiC grains at temperatures exceeding 2,100°C. These elements are generally porous (8-25%), allowing interaction between the furnace atmosphere and the material. Over time, the heating element may experience gradual oxidation, leading to an increase in electrical resistance, a phenomenon known as ‘aging.’ To maintain consistent power output, a variable voltage supply is often employed to incrementally increase the voltage as the element ages. This aging process ultimately limits the lifespan and performance of the heating element.

Silicon carbide is particularly suited for high-temperature applications due to several key properties. It does not have a liquid phase, which means it resists sagging or deforming due to creep at high temperatures, eliminating the need for internal supports within the furnace. SiC sublimates directly at around 2,700°C, making it ideal for extreme conditions. Additionally, it is chemically inert to most process fluids, possesses high rigidity, and has a low coefficient of thermal expansion. Silicon carbide heaters can reach temperatures of approximately 1,600 to 1,700°C.

Graphite, a mineral with a hexagonal atomic structure composed of carbon, is an excellent conductor of heat and electricity, capable of generating heat at temperatures exceeding 2,000°C. At elevated temperatures, graphite’s electrical resistance increases significantly. It also exhibits excellent resistance to thermal shocks, maintaining its integrity without becoming brittle during rapid heating and cooling cycles. However, a significant drawback of graphite is its tendency to oxidize at around 500°C, leading to material degradation over time. As a result, graphite heating elements are primarily used in vacuum furnaces, where oxygen and other gases are removed from the heating chamber to prevent oxidation of both the molten metals and the heating element itself.

Refractory metals like tungsten and molybdenum share similar properties with graphite when utilized as heating elements. Tungsten can function at the highest temperatures among these metals but is also the most costly. Molybdenum, although less expensive and more frequently used, still costs more than graphite. Similar to graphite, these metals need to be used in vacuum conditions due to their strong affinity for oxygen, hydrogen, and nitrogen. They start to oxidize at temperatures ranging from 300 to 500°C.

Typical PTC (Positive Temperature Coefficient) materials include rubber and ceramics. PTC rubber is typically composed of polydimethylsiloxane (PDMS) embedded with carbon nanoparticles. PTC heaters are notable for their ability to regulate current flow by increasing electrical resistance as the temperature rises. This feature makes them safe and ideal for applications like heated clothing. Initially, the heater draws full power and heats up due to its resistivity. As the temperature climbs, the material’s resistance increases, eventually functioning as an insulator. This self-regulating behavior occurs without the need for an external feedback mechanism.

A heating system includes more than just the heating element. It also comprises terminations, leads, insulation, packing, sheath, and seals. Heaters come in various forms and configurations to meet specific application needs. Below are some of the most common types of heaters and their applications.

Air Process Heaters: These heaters are designed to warm flowing air. Essentially, an air process heater consists of a heated tube or pipe with an inlet for cold air and an outlet for hot air. The interior walls of the pipe are lined with coils of heating elements, which are insulated by ceramics and non-conductive gaskets. They are commonly used in high-flow, low-pressure scenarios. Typical applications include heat shrinking, laminating, adhesive activation or curing, drying, and baking.

Cartridge Heaters: In this type of heater, the resistance wire is wound around a ceramic core, often made from compacted magnesium oxide. Rectangular configurations are also available, where the resistance wire coils traverse the length of the cartridge three to five times. The heating element is positioned close to the walls of the sheathing material to ensure optimal heat transfer. To safeguard the internal components, the sheath is typically constructed from corrosion-resistant materials like stainless steel. The leads are generally flexible, with both terminations located at one end of the cartridge. Cartridge heaters are commonly used for die or mold heating, fluid heating (as immersion heaters), and surface heating.

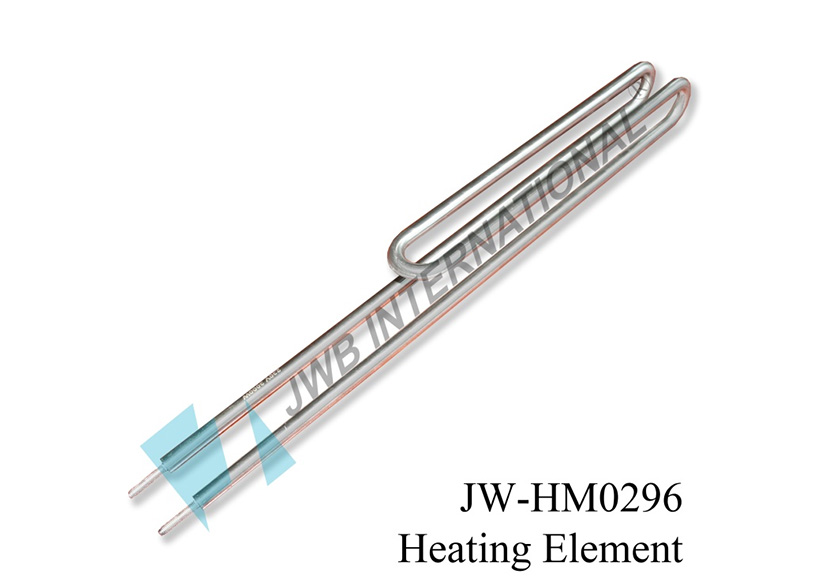

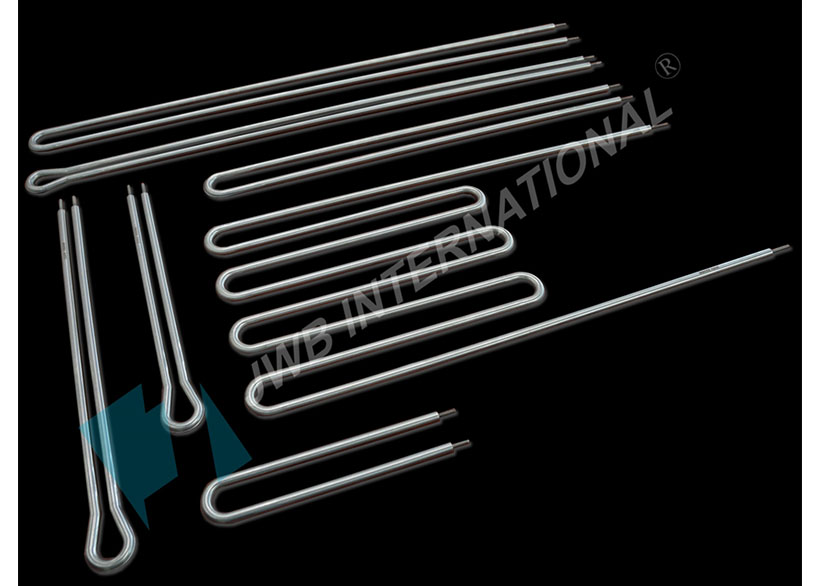

Tubular Heaters: Tubular heaters have internal components similar to those of cartridge heaters. The primary distinction is that the lead terminals are located at opposite ends of the tube. The tubular design allows for bending into various shapes to meet specific heat distribution needs for a given space or surface. Additionally, these heaters can be equipped with fins mechanically bonded to the sheath surface to enhance heat transfer efficiency. Tubular heaters are highly versatile, much like cartridge heaters, and are used in comparable applications.

Band Heaters: These heaters are specifically designed to encircle cylindrical metal surfaces or containers, including pipes, barrels, drums, and extruders. They come with bolted locking tabs to ensure a secure attachment to the container’s surface. Inside the band, a thin resistance wire or ribbon is typically insulated by a mica layer. The outer sheath is made from materials like stainless steel or brass. One key advantage of band heaters is their ability to indirectly heat the fluid inside the vessel, protecting the heater from chemical attacks by the process fluid. This also reduces the risk of ignition when used with oils and lubricants.

Strip Heaters: This type of heater is flat and rectangular, designed to be bolted onto the surface that needs heating. Internally, it resembles a band heater but can use insulating materials such as ceramics like magnesium oxide and fiberglass, in addition to mica. Strip heaters are commonly used for surface heating applications involving dies, molds, platens, tanks, and ducts. They can also be adapted for air or fluid heating by incorporating finned surfaces. Finned strip heaters are often found in ovens and space heaters.

Etched Foil Heaters: Etched foil heaters, also known as thin-film heaters, feature a resistive heating material that is etched and bonded onto a foil, typically made of aluminum. For applications requiring greater flexibility and tear resistance, the substrate can be made from heat-resistant synthetic rubber or thermoplastic polyurethane (TPU). One of the key benefits of etched foil heaters is the close spacing of the heating elements, made possible by photochemical etching. This allows for even heat distribution and higher heat density in compact forms. These heaters are more specialized compared to conventional wire heaters and are commonly used in medical devices, electronics, instrumentation, aerospace, and clothing. Additionally, one side of the heater can be lined with an adhesive layer for easy mounting.

Ceramic Heaters: These heaters utilize ceramics known for their high melting points, thermal stability, high-temperature strength, relative chemical inertness, and low heat capacity. It’s important to note that these ceramics differ from those used as insulating materials. Due to their excellent thermal conductivity, these ceramics are employed to conduct and distribute heat from the heating element. Notable examples include silicon nitride and aluminum nitride, which are often used for rapid heating applications such as glow plugs and igniters. However, these materials can be prone to cracking when exposed to rapid high-temperature heating and cooling cycles due to thermal stress-induced fatigue. A specialized type of ceramic heater is the PTC (Positive Temperature Coefficient) ceramic heater, which can self-regulate its power consumption, preventing it from becoming red hot.

Ceramic Fiber Heaters: In this type of heater, ceramic fiber serves as an insulator to focus heat on the target surface, minimizing system losses. Ceramic fiber pads feature a resistance wire wound on one side, which is then bonded to the surface that needs heating. These heaters can achieve temperatures up to 1,200°C.

Although heating elements typically function based on the same fundamental principle, their performance and longevity are affected by various factors. Important specifications for heaters include power or wattage, maximum operating temperature, type of process fluid, sheath material, and power supply (voltage and frequency). Moreover, considerations such as fluid flow and temperature control are crucial for optimizing performance.

Watt Density: Watt density refers to the amount of heat a heating element delivers per unit area. Choosing the appropriate watt density for a specific application is essential to maximize the heater’s service life. It’s important to note that for a given wattage, both high and low-density heaters will produce the same amount of heat, but at different temperatures. High-density elements can achieve significantly higher temperatures, which may result in premature burning or failure of the element. When selecting a heating element, always consult the manufacturer’s recommended watt densities for the intended application.

Temperature: The target operating temperature has a direct impact on the watt density, necessitating a balance between the two factors. When designing a process heater, the temperature is typically determined first, as it is often a critical process parameter required by the system.

Power Supply: The heating element must be compatible with the available power supply. Typically, voltage ratings are either 120V or 240V. When selecting a target wattage, ensure you verify the resulting amperage. It’s crucial to avoid exceeding the circuit breaker’s tripping point or the power cables’ ratings.

Fluid Flow: Intuitively, stagnant fluids are easier to heat with controlled temperatures compared to flowing fluids. Air and other gases typically do not absorb heat quickly due to their low density. While slowing down the flow could be a solution, it is often not feasible. Therefore, heaters with large surface areas are necessary. Air heaters commonly feature finned surfaces and long wire coils, which are characteristics of low-density heating elements.

Temperature Sensor Location: Traditional heaters are typically equipped with a temperature sensor and a controller. In many applications, the sensor only measures the temperature of the process fluid, which often does not accurately represent the actual temperature of the heating element. Before installing the heater and the temperature sensor, ensure that the sensor’s location is suitable for the heater unit. If the sensor is positioned too far away, the measured temperature may be significantly lower due to heat dissipation and a low heat transfer rate. This discrepancy can result in excessively high temperatures that may damage the heating element.

Corrosion: Corrosion can originate from either the process fluid or the external environment. The sheathing material serves to protect the heating element, leads, and insulators from chemical damage. Therefore, the sheath must retain its strength at high temperatures while also being resistant to corrosion. Commonly used sheathing materials include stainless steel, brass, copper, and specialized alloys like Monel and Incoloy. Additionally, the integrity of the sheath and terminal sealing must be adequate for the specific application. For demanding environments, hermetic sealing is the optimal choice to ensure complete protection from the process fluid.

A heating element is a material or device that directly converts electrical energy into heat or thermal energy through a principle known as Joule heating.

The most important heating element characteristics are sufficient resistivity, high oxidation resistance, low-temperature coefficient of resistance, high toughness, and high melting point.

Widely used heating elements are nickel-chromium alloy, iron-chromium-aluminum alloy, molybdenum disilicide, and silicon carbide. These are followed by graphite and other refractory metals which generally have higher oxidation rates.

Aside from the heating element, a heater consists of the terminations, leads, insulation, packing, sheath, and seals. These heaters have various forms and configurations to suit a particular application.

Typical heater ordering specifications are the power or wattage, maximum operating temperature, type of process fluid, sheath material, and power supply (voltage and frequency).