Aluminum extrusion molding is a processing technology that heats aluminum alloy materials to a plastic state, and then applies high pressure to force the aluminum billet in the mold cavity (or extrusion barrel) to produce plastic deformation to form a product with a specific cross-sectional shape.

Here, we need to distinguish the difference between extrusion and casting briefly. Extrusion is usually a continuous process, suitable for producing long strips or parts with a specific cross-section. Casting, on the other hand, is to heat the metal to a liquid state, then pour it into a pre-designed mold, and wait for it to cool and solidify to obtain a part of the desired shape. Casting is a static process, suitable for the production of complex or large parts.

Typically, the temperature of aluminum alloys is heated to 400 to 500 degrees Celsius to give it good plasticity and fluidity. The extruded aluminum profile is cooled to maintain its shape, and the cooling method can be air cooling or water cooling, and then cut into the required length. Depending on the needs, the aluminum profile may also undergo subsequent processes such as heat treatment and surface treatment to improve its mechanical properties, corrosion resistance or appearance quality.

Aluminum extrusion is widely used in many industries such as construction, automobiles, aerospace and electronics to produce products such as door and window frames, radiators, structural supports, etc. The advantage of this process is that it can produce complex shapes, has high material utilization, good mechanical properties and corrosion resistance, so it occupies an important position in modern industry.

Direct extrusion and indirect extrusion are two common aluminum alloy extrusion processes. The main difference between them is the direction of movement of the metal billet and the extrusion method.

1. Direct/forward aluminum extrusion

Direct aluminum extrusion refers to the process in which the metal billet is pushed into the die in the same direction as the extrusion direction during the extrusion process. In this process, the aluminum alloy billet is pushed into the die by the pressure of the extruder, and the metal flow direction is consistent with the pressure direction, that is, the metal enters from one port of the die and is finally extruded from the other port.

Direct aluminum extrusion is a relatively simple and low-cost process, which is often used to produce standard profiles. Its advantages are simple equipment structure and low energy consumption, but due to the large friction between the billet and the die, the flow of the metal may not be as smooth as indirect extrusion, which is easy to cause internal stress and defects.

2. Indirect/reverse extrusion

Indirect aluminum extrusion refers to the relative movement of the metal billet and the pusher (such as a piston) of the extruder. In the indirect extrusion process, the aluminum alloy billet is placed in a fixed container, and the pusher of the extruder pushes the metal to the die mouth from the other end of the die, and the metal flows in the opposite direction of the pressure. That is, the metal flows out of the die outlet, while the pusher pushes the billet at the other end.

This process can effectively reduce the friction between the metal and the die, so that the metal flows more evenly, reduces internal stress, and can produce higher quality aluminum profiles. Since the equipment of indirect extrusion is complex and the manufacturing cost is high, it is mainly used in occasions with high product quality requirements.

According to the cross-sectional shape of the aluminum profile, extrusion dies can be divided into several types. Each die is designed to meet the specific cross-sectional shape requirements to ensure the quality and precision of the final aluminum profile. Common types of extrusion dies include:

• Single profile die: This die is designed to produce aluminum profiles with a single cross-sectional shape, such as regular profiles such as rectangular, square, and round. Given that the cross-sectional shapes of these profiles are relatively regular and simple, they are well-suited for mass production of standard aluminum extrusion shapes.

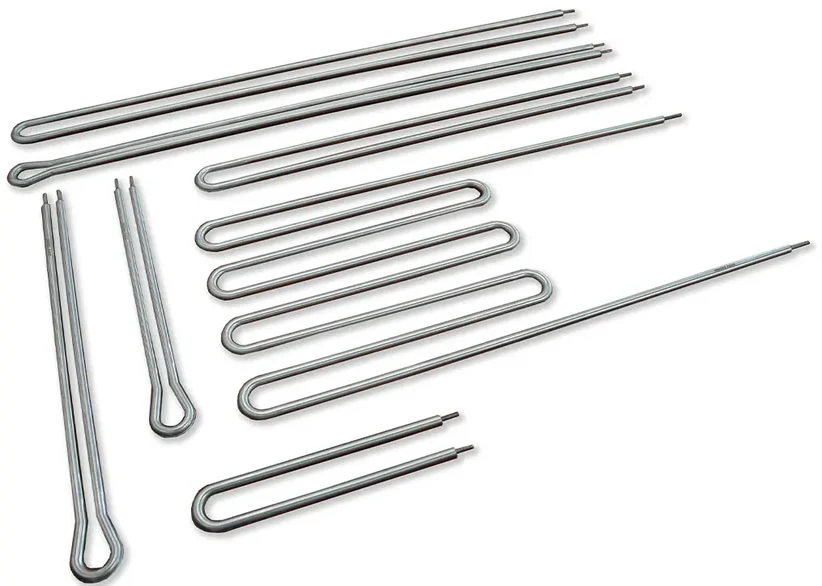

• Complex profile molds: Used to produce aluminum profiles with complex geometric shapes, such as T-shaped, L-shaped, U-shaped, I-shaped, angle steel, etc. Usually used to manufacture high-precision products such as structural parts and support parts.

• Multi-cavity molds: Multi-cavity molds are designed with multiple cavities, which can extrude multiple aluminum profiles of the same or similar shapes at one time. This mold is usually used to produce aluminum profiles with hollow structures, such as aluminum tubes, aluminum grooves, U-shaped tubes, etc. These profiles are widely used in fields such as pipes or frames. Multi-cavity molds are also commonly used in mass production of standard profiles.

• Hollow profile molds: This mold is specially used to produce hollow cross-sectional aluminum profiles, such as aluminum tubes, aluminum grooves, etc. These profiles have a hollow structure in the middle of the cross section and are usually used in applications that require pipes or frames. The design of hollow molds is relatively complex, and the size and wall thickness of the hollow part need to be precisely controlled.

• Complex section profile molds: Used to produce aluminum profiles with special shapes and complex sections (such as curves, bends, double-layer structures, etc.). The design of complex section profile molds requires high precision, and usually requires the use of split mold technology or cooling systems to ensure the stability and surface quality of the aluminum profile.

• Multifunctional composite molds: Composite molds combine designs of different shapes or functions, and can extrude different aluminum profiles or perform different processing processes in the same mold at the same time. They are usually used to produce aluminum profiles with multiple functions, such as combined profiles, profiles with slots or connecting parts, etc.

Aluminum extrusion molding process is widely used in multiple industries, especially in products that require lightweight, high-strength materials and complex shapes. The following are some common applications of aluminum extrusion molding process:

1. Construction industry: Aluminum profiles have good corrosion resistance, plasticity and strength, and are often used in the manufacture of door and window frames, shading facilities and other products in the construction industry.

2. Transportation: Aluminum extrusion is widely used in automobiles, railways, aerospace and other fields. In the automotive industry, aluminum alloy extrusion profiles are used to manufacture body frames, support structures, radiators, rims and other parts. In the aerospace field, aluminum profiles are often used to manufacture aircraft structural parts, wing frames and spacecraft components.

3. Electronic and electrical industry: Aluminum extrusion is used to manufacture electronic product housings, radiators, frames, connectors, etc. The excellent thermal conductivity of aluminum alloys makes it a common heat dissipation material in electronic products, especially in LED lighting, computer equipment and communication equipment.

4. Solar industry: In the solar industry, aluminum extrusion molding is used to produce solar frames and bracket systems. These aluminum profiles can be used to support the installation of solar panels, provide stable and durable support structures, and have good corrosion resistance.

5. Home appliance industry: In the home appliance industry, aluminum extrusion is often used to produce home appliance housings, radiators, fan frames, etc. Aluminum profiles can provide lightweight and good heat dissipation performance, suitable for the manufacture of products such as air conditioners, refrigerators, washing machines, etc.