CNC machining (Computer Numerical Control Machining) is an advanced automated manufacturing technology that uses preprogrammed computer instructions to precisely control the movement of machine tools and tools, removing material from a workpiece and shaping parts or products that meet design requirements. The core of CNC is to use digital design models (typically created with CAD software) to generate instructions (G-code and M-code) that the machine tool can understand, controlling the movement of the cutting tool along the X, Y, and Z axes.

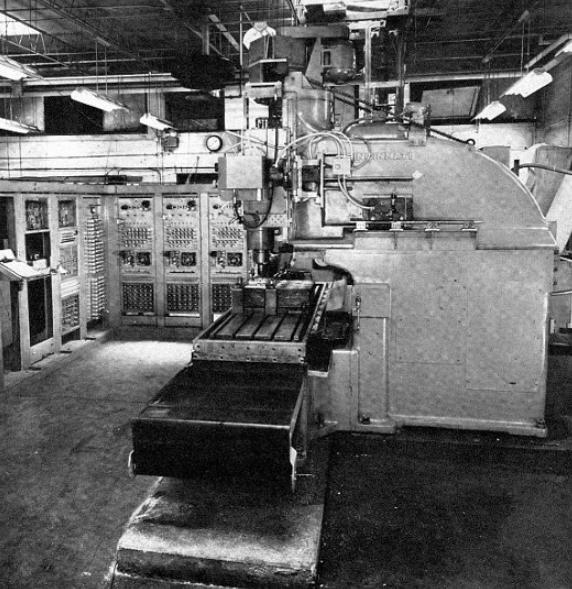

The prototype of CNC machining can be traced back to ancient hand carving and machining, but the birth of modern CNC technology began in the 1940s. In 1949, John T. Parsons developed a technology for controlling the movement of machine tools through motors at the Massachusetts Institute of Technology (MIT) for the US Air Force to manufacture helicopter blades and aircraft frames. This technology laid the foundation for numerical control (NC).

In the late 1950s, MIT and the U.S. Air Force collaborated on a project aimed at further improving manufacturing efficiency and precision. This collaboration led to the invention of computer numerical control (CNC), which replaced punched cards with computer-generated data to control machine tools.

In 1972, computer-aided design (CAD) and computer-aided manufacturing (CAM) systems began to emerge. CAD software allowed engineers to create detailed 3D models of designs, while CAM software converted these designs into instructions readable by CNC machines. In 1976, CAD and CAM systems were incorporated into CNC machining. By 1989, machine tools controlled by CAD and CAM software had become the industry standard for CNC machine tools.

CNC machining uses computer programs to drive machine tools to complete the automated process from design to finished product. Its workflow can be divided into four key steps:

Step 1: Create a CAD Model

The first step in machining is to create a 2D or 3D model of the part using computer-aided design (CAD) software. Common software includes SolidWorks , AutoCAD, and the open-source FreeCAD . Complex parts may require breaking the design down into multiple subassemblies, each with its own CAD model. Beginners can quickly master the basics of CAD using online tutorials, but complex designs typically require the involvement of a professional designer.

Step 2: CNC Programming

CNC machines cannot directly read CAD files; they must be converted into G-code (geometry code). G-code defines the machine's motion trajectory and operating parameters. For example, G01 X10 Y20 means the tool moves along a straight line to coordinates (X=10, Y=20). Some CAD software, such as Fusion 360, supports direct G-code generation. Complex projects often use computer-aided manufacturing (CAM) software, such as Mastercam , to optimize machining paths, reduce cutting time, and reduce tool wear. CAM software can also simulate the machining process, identifying potential errors before they occur.

Step 3: Perform CNC Machining

Load and run a G-code program through the machine's control panel. The machine automatically follows the instructions to perform operations such as cutting, drilling, or grinding. For example, machining a mobile phone case might involve milling a flat surface, drilling screw holes, and engraving a brand logo. The machining process typically requires no human intervention unless manually paused by the operator or a fault occurs (such as a broken tool or power outage). Modern CNC machine tools are equipped with sensors that monitor machining status in real time and automatically alert you to any abnormalities.

CNC machining covers a variety of processes, each targeted at specific materials and part requirements. The main types include: CNC milling, CNC turning, CNC drilling, CNC grinding, CNC

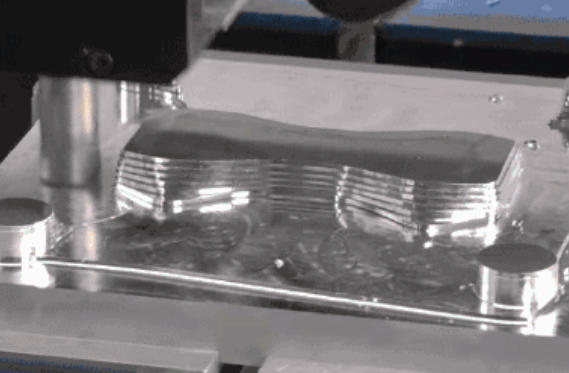

CNC milling

CNC milling uses a milling cutter to remove material from a workpiece and precisely machine it to the required specifications. The workpiece is typically held in position while a high-speed moving cutting tool removes material from it. CNC milling machines can use a variety of cutting tools, each with a different purpose. Typical cutting tools include end mills, reamers, face mills, and taps. CNC milling is suitable for machining flat surfaces, slots, holes, and complex curved surfaces. For example, machining a mold might require a 5-axis milling machine to achieve cutting at multiple angles.

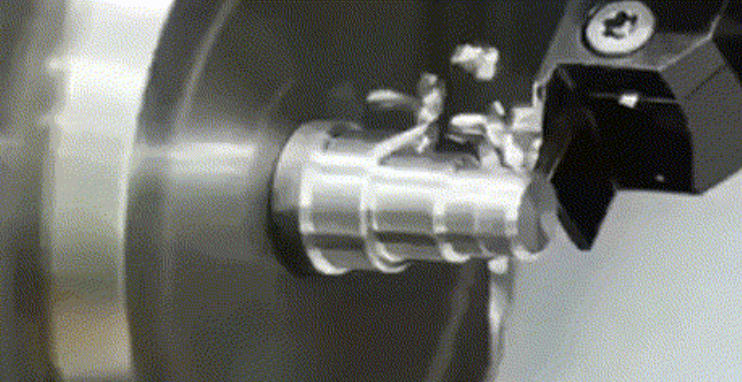

CNC turning

CNC turning (lathe machining) involves holding a material such as metal or plastic in a rotating chuck. A cutting tool removes material from the rotating workpiece evenly until the desired shape is achieved. CNC turning is suitable for producing cylindrical or symmetrical parts.

CNC drilling

CNC drilling uses a rotating drill bit to create holes in a workpiece. The process is simple and efficient. For example, mounting holes on circuit boards are often completed by CNC drilling.

CNC grinding

CNC grinding uses high-speed grinding wheels to fine-tune the surface of a workpiece to a high finish. It is commonly used for precision parts such as bearings and gears. The type of grinding wheel (such as diamond or aluminum oxide) is selected according to the material.

Laser cutting : Uses a laser beam to cut metal, plastic or wood with an accuracy of up to 0.1mm.

Plasma cutting : Cuts conductive materials using a high-temperature plasma arc, suitable for thick steel plates.

Water jet cutting : uses high-pressure water jets to cut a variety of materials without heat-affected zones, suitable for stone and glass.

Electrospark machining (EDM) : melts materials through electric sparks and is suitable for processing complex molds.

CNC machining supports a variety of materials to meet the needs of different industries:

aluminum alloy

Aluminum alloy is a widely used metal material characterized by its light weight, high strength, ease of processing, and excellent corrosion resistance. Aluminum has a density of approximately 2.7g/cm³, only one-third that of copper and steel.

Commonly used aluminum alloy grades include: 1060, 2A12, 2024, 5052, 6061, 6063, 7075, etc.

Stainless steel

Stainless steel is an alloy steel composed of several metals in varying proportions. It primarily contains carbon, iron, chromium, nickel, and molybdenum . Chromium must account for at least 10.5% of the alloy to qualify as stainless steel. Stainless steel offers high strength, ductility, wear resistance, corrosion resistance, and is easy to weld, machine, and polish. Different proportions of stainless steel result in distinct properties and applications.

Commonly used stainless steel grades include: 301, 303, 304, 304L, 316, 316L, 420, 430, 440C, 17-4PH, etc.

brass

Brass is a copper alloy composed of copper and zinc . It is ductile, wear-resistant, corrosion-resistant, easy to process and conductive.

Commonly used brass grades include: H59, H62, etc.

titanium alloy

Titanium alloy is a good material for CNC machine tools because it is strong and lightweight. It does not rust easily and is safe for use in the human body (biocompatible).

Commonly used titanium alloy grades include: TA1, TA2, TA5, TC4, etc.

ABS-engineering plastics

ABS is a material made from the combination of three compounds: acrylonitrile, butadiene, and styrene. The English initials are taken to form ABS, and the full Chinese name is "Acrylonitrile-Butadiene-Styrene".

ABS combines the material properties of three compounds, offering oil resistance, high stability, strength, impact resistance, transparency, colorlessness, excellent fluidity, and low density. In CNC machining, it is commonly used for electronic and electrical housings, automotive parts, machine tools, Lego, clothing buttons, cabinets, stationery, hard hats, battery boxes, and more.

PC-polycarbonate

Polycarbonate is a plastic material that is highly tough, has high impact strength (higher than ABS), is transparent and colorless, heat-resistant, and is easy to process and color.

POM -Saigang

Polyformaldehyde (PO ), also known as polyoxymethylene ( PAM ) , offers high tensile strength , impact resistance, strong corrosion resistance to gasoline, solvents, and other chemicals, and possesses physical properties similar to metal, making it the easiest of all plastic materials to process. Polyoxymethylene (PAM) is commonly used in automobiles, home appliances, construction, electronics, and sanitary products.

PTFE -Teflon

PTFE ( Polytetrafluoroethene ), commonly known as Teflon , boasts excellent weather resistance, insulation, abrasion resistance, non-stick properties, and acid and alkali resistance, earning it the reputation of the "king of plastics." It's also one of the few plastics that can withstand temperatures exceeding 200 °C .

HDPE-High Density Polyethylene

HDPE (High Density Polyethylene) has the characteristics of good chemical tolerance, strong toughness, strong elasticity, good weather resistance, etc. It is easy to process, low cost, and can come into contact with food.

PEEK-Polyetheretherketone

PEEK ( Polyetheretherketone ) has extremely high heat and chemical resistance, can withstand temperatures exceeding 260 °C , and can be used for extended periods in harsh environments. Compared to other plastic materials, PEEK is more expensive.

CNC machining include:

High Precision: CNC-machined parts are produced to precise specifications, eliminating the need for constant attention from specialists and operators. Because they are computer-controlled, the potential for human error is negligible. CNC machining can achieve tolerances up to ±0.005mm, meeting the demands of demanding industries such as aerospace and medical.

High Efficiency : Automated CNC machining methods minimize the need for human intervention, resulting in faster and more consistent production throughout the manufacturing cycle. Using pre-programmed instructions, CNC machines can repeatedly reproduce identical parts. For example, traditional manual machining of a part might take hours, while CNC machining can take only minutes.

Complex Geometry Machining: CNC machines offer up to six machining axes, providing the ability to manufacture complex parts. Typically, manufacturing parts using a machine requires multiple setups to create all features. Higher axis capabilities reduce the number of setups required, thereby enhancing the potential for manufacturing highly complex CNC machined parts. For example, 5-axis machining can cut angles beyond the capabilities of 3-axis machines.

CNC machining is indispensable in many industries. The following are the main application scenarios:

Aerospace : Producing high-precision parts such as turbine blades and landing gear, ensuring lightweight and safety.

Automotive manufacturing : Manufacturing engine blocks, drive shafts, and interior parts to improve performance and fuel efficiency.

Medical devices : Production of orthopedic implants and surgical instruments that meet biocompatibility requirements.

Electronics industry : Processing circuit board brackets, radiators and equipment housings to meet miniaturization and high heat dissipation requirements.

Architecture and Art : Carving complex stone patterns, such as marble countertops, enhances decorative effects.

Robotics and Automation : Rapid prototyping to support the development of robot joints and enclosures.